Categories

- Composites, Plastics & Rubber

- Electrical, Electronics & Electro-optics

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Metal Processing, Parts & Components

- Services (R&D, training, engineering, consultancy, …)

S.G.D Engineering Ltd., is a leading provider of Airborne Mission Solutions. Over the past 30 years the company has successfully completed more than 140 projects worldwide. S.G.D delivers tailored solutions for most stringent customer requirements, needs and expectations, on a variety of aircraft platforms. Among S.G.D's customers are governments, leading aerospace industries as well as airborne systems providers. S.G.D is active in worldwide markets as the US, Asia Pacific, Lat. America and Europe.

S.G.D offers high value turn key projects from concept development to serial production. These include design, analyses, testing, aircraft integration, installation, production and certification of various Airborne systems.

SGD main product lines are:

• Airborne Pods - from development to serial production.

• Special Mission Aircraft - for fixed and rotary wing.

Airborne Pods

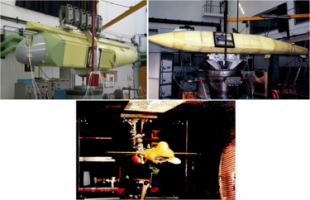

S.G.D Engineering Ltd. is a reputable world leader in design, integration, production and certification of airborne pods. S.G.D provides fully equipped airborne pod ready for integration with specific sensor systems. S.G.D's airborne pod package generally consists of pod structure, radomes, Environmental Control Systems (ECS), wire harnesses, power management, power generation systems and pressurization system when required. The company developed airborne pods with airborne sensors and systems such as Reconnaissance Cameras (Recce Pod), Synthetic Aperture Radar (SAR Pod), EW Pod, Self Protection Pod with or without RWR/MWS sensors, chaff and flares dispensers etc.

S.G.D's airborne pod programs experience includes pod development and production for various platforms. Among the pods that have been developed by S.G.D are F-16 pod, F-15 pod, F-4 pod and Tornado pod. The company develops pods mounted with pylons and adapters or conformal pods. S.G.D's Pods are designed for defense industry market leaders as Lockheed Martin, Goodrich Corporation, and are being operational in many air forces worldwide.

For all pods S.G.D provides the following capabilities and expertise:

• Mission requirements analyses

• Structural design

• Stress and structural analyses

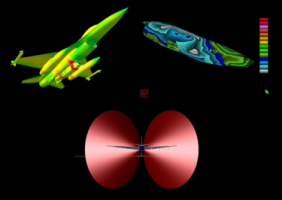

• Aerodynamic and CFD analyses

• Aero-optic analyses

• Thermodynamic analyses

• Environmental Control Systems (ECS)

• Electric power management and distribution

• Wire harness design, routing and installation

• Radomes, radiation analyses and testing

• Aircraft integration

• Wind tunnel and ground tests

• Flight tests

• Certification

• Production and assembly

• Ground Support Equipment (GSE)

• Training and documentation

Special Mission Aircraft

S.G.D provides a wide range of conversions to Special Mission Aircraft for both defense and Homeland Security applications. S.G.D's Special Mission Aircraft solutions are being tailored to the customers operational needs on any required airborne platform (Fixed and Rotary wing aircraft) for applications such as ISR aircraft (Intelligence, Surveillance and Reconnaissance), EW aircraft (Electronic warfare ), and Maritime Patrol aircraft.

S.G.D's capabilities and experience in Special Mission Aircraft benefit the customer at all the program aspects:

Turn key program:

S.G.D is able to offer full turn key Special Mission Aircraft projects based on the experience and know-how gained over more then 140 projects world wide. Whether the customer needs a new overall solution or wants to upgrade his existent one, S.G.D can meet his need.

Mission Systems:

S.G.D's alliances with world's leading Airborne Mission Systems providers allow the company to propose and deliver state of the art proven sensors and systems which are evaluated and selected to meet the customer's operational requirements and provide best performance to cost effective solution. S.G.D's experience consists of conversion programs performance which includes in general EO/IR payloads, weapons, avionic upgrades, SIGINT systems, data link and Self protection suites.

Aircraft Conversion:

S.G.D's solutions are designed to offer the optimal modification of the aircraft to fit its new mission and systems. Including: external installation (sensors, antennas etc.), cockpit upgrade, operators’ command and control workstations, seats, wiring, pylons, adapters and all other necessary tailored solutions, installations, integrations and certifications.

Design

S.G.D specializes in the design of airframe and airborne systems including new systems installation and integration, aircraft modifications, upgrades and conversions. S.G.D's detailed design-mechanical, electrical and software, is tailored to meet customers specific requirements based on applicable Civil and Military Standards.

Mechanical Design is performed using various 3D solid modeling CAD systems.

• Based on customer's requirements the company uses:

• Uni Graphics

• CATIA

• Pro-Engineering

• Cimatron

Analysis

Analyses & Simulations:

The company’s Analyses Group Supports a wide-range of capabilities to ensure the integrity of all S.G.D’s designs.

S.G.D provides a comprehensive set of analyses and simulations such as:

• Loads Analyses

• Stress Analyses- linear and nonlinear

• Thermal Analyses

• Aerodynamic Analyses

• Computational Fluid Dynamics (CFD) - loads, Stability & Control, Drag & Performance

• Dynamic and Modal Analyses

• Fatigue analyses

Integration

System engineering and Integrations of new systems on board an aircraft require experience, know-how and systematic approach.

S.G.D delivers integrated solutions, based on the specifications and performances requirements of its customers.

The company's Integration package includes mechanical and communications integration, wiring and installation. S.G.D integrates systems and components to work together as one unit and with the aircraft existent systems.

The integration is done from the system architecture design, development of control and processing units, performance of System Integration Lab (SIL) tests, Installation in the aircraft and full ground and flight testing.

Installation

S.G.D has vast Installations experience. The company has successfully completed installations on variety of platforms, on fixed and rotary wing aircraft.

The Installation is carried out by S.G.D’s experienced and qualified technicians (structures, mechanics, and electricians), as all installations are preformed under S.G.D’s engineers guidance and supervision.

S.G.D can implement the installation according to the location the customer desire, at the customer premises, or in facilities offered by S.G.D.

Testing

S.G.D has the expertise to plan and perform the relevant ground and flight tests, as required to certify its products. S.G.D support:

• Ground Static tests

• Ground Vibration Test

• Wind Tunnel Tests

• Safety of Flights Tests

• Environmental Tests

• Ground Fit & Function Tests

• Heat transfer Tests

• EMI/RFI

• Radomes radiation tests

• Flight Tests- envelope clearance, Performance evaluation

• Instrumented flight Tests

Certification

S.G.D supports the Certification process according to applicable requirements such as FAR, MIL-SPECs and specific customer’s authority’s requirements such as FAA, EASA, CAA or Military Authorities.

The company certified a large number of modifications and installations on civil and military aircraft.

The Certification package as per the certifying authority requirement and include as a minimum:

• Production, Assembly and Installation drawings and all engineering documents

• Analyses documents and reports

• Qualification documentation for LRU’s

• Tests documents (test plan, test procedure, test results and evaluation)

• Ground tests

• Wind Tunnel tests

• Safety of flight

• Flight tests

The process is complete after receipt the Airworthiness Certificate of the modified aircraft from the relevant authority.

Production and Assembly Plant

As performing Turn Key projects, S.G.D is delivering the certified product as part of the program, to its customers. Some parts and components are produced by subcontractors who are fully certified for the product.

All products from pods to variety of kits are assembled in house in the company's assembly plant by SGD’s qualified technicians, under S.G.D’s engineers and quality control organization supervision. The plant, as well as all other functions of the company, is certified to AS 9100 and all products meet the quality standards for airborne equipment.

S.G.D. Engineering Ltd.

- 38 Habarzel St., 6971054, Tel Aviv, Israel

- +972 3 5604135

- +972 3 5602179

- marketing@sgd.co.il

- www.sgd.co.il