Categories

- Aircraft, Helicopter, UAV, Spacecraft & related equipment

- Electrical, Electronics & Electro-optics

- IT, Computing and Software

- Mechanical, Electro-mechanical, Hydraulic and Pneumatic components

- Metal Processing, Parts & Components

- Military, Tactical, Logistic Support Vehicles & related equipment

- Radar, Sonar, Navigation, Targeting, Surveillance

- Services (R&D, training, engineering, consultancy, …)

- Ships, Vessels, Submarines & related equipment

Devotek AS, (former Kongsberg Devotek) is an independent multi technology provider and specialist in dynamic systems, actuators and drivelines. Devotek is a leading independent technology provider with 30 years’ of experience within a wide range of technologies and services. Working for industries like defence, automotive, oil & gas, energy, maritime and telecom gives the company a broad background for applying the state of the art solutions to many challenges.

Core competences are within areas linked to control of dynamic systems. It covers areas as driveline design and control within:

- Vehicles,

- Ships,

- Helicopters, including transmission design,

- Actuators,

- Electronic control design,

- Sensors,

- Hydraulics,

- Clutch and brakes and much more.

Systems Engineering

Devotek is known for its systematic approach to technical challenges as it completes development and technology projects according to the Systems Engineering methodology. The company focuses highly on Quality Management according to internationally recognised QMS standards.

The company ensures understanding of the user requirements, thorough concept studies and technology bench marking, careful quality assured concept selection, prototyping and testing, all parts of the Devotek methodically design processes.

Project areas:

Defence & Space

Systems and products for defence applications are characterized by top performance at extreme environments. This is where Devotek experience and competence will be at its best. Smart design solutions, clever design, protection and packaging of electronics, verifications by advanced simulations and final approval and acceptance by testing will ensure product that will perform at all conditions.

Automotive

-

25 years of experience with automation of transmissions since early 80’s. General development, including safety systems, since 2001

-

Competence and focus on dynamics of mechatronic systems. The company handles the full range from concept generation system validation

-

Highly involved in DCT transmission development and hybridization. The company can take on full automation system responsibility, both HW and SW

-

Electromotoric and hydraulic transmission automation solutions currently in series production

-

Innovative solutions for crash protection systems currently in series production

-

Large number of fully functional prototype and demonstration vehicles

Oil & gas

The technological challenges of always discovering new recourses, recovering more oil or improving existing processing capabilities will require the best competence in the field. Devotek expertise is fit to solve the challenges faced by the Oil & Gas industry. With experience from several Offshore projects, Exploration and Drilling, Top side or Subsea, Devotek will support our customers in finding the best technological solutions for the challenges ahead.

Industry

Devotek has a long tradition in product and component development for different industries. The different businesses are all challenging, and have often similar multi-technological demands.

Typical assignments:

- Concept generation, prototype and module design within areas like Mechatronics often in combination with static or dynamic analysis

- Digital or analogue electronics Control system combined with application software

- Prototype generation, production and test

- The company prefers to perform the projects in its development centers were it can put together a tailored team of specialists

Maritime

Devotek has extensive experience in working with applications for the maritime industry. Typical design and development assignments:

-

Propulsion systems

-

Deck machinery

-

Loading and off-loading units

-

Control and guiding systems

With its cross-disciplinary expertise it can present optimized solution to its customers.

Services

Based in Kongsberg, Devotek’s cross-disciplinary expertise has enabled the successful development of solutions for a wide range of industrial environments – from the ocean floor to outer space. As a partner in process, customers can call upon experts in the field of:

- Mechanical,

- Electronic and software specification design and testing;

- Control systems design,

- Testing and analysis;

- Mathematics and applied physics;

- Prototyping and validation programmes;

- Safety evaluation, and

- Quality control.

Contact info #1

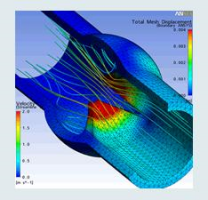

FEA & CFD Analysis

Some of the services the company offers are:

- Advanced dynamic, non-linear and static simulations

- Thermal and CFD simulations and analysis

- Applications: Electronic cooling and vibration, non-linear system analysis, random vibration, fluid and thermal analysis, non-linear material behavior, non-linear contact analysis

- FEM analysis using analysis software as MSC Nastran, MSC Marc, MSC Dytran, MSC Adams, MSC Patran, NX Nastran, Abaqus, Star-CCM, I-DEAS and Unigraphics NX

- Proactive interaction with designers to ensure optimal product design

DYNAMICS & CONTROL

Some of the services the company offers are:

- Mathematical modelling and analysis of system dynamics and interaction

- Analysis and implementation of control system based on requirements of performance, stability and robustness

- Analysis of existing control systems to identify possible improvements

- Development of simulator systems ( Matlab/Simulink) for easy survey of system behaviour over various scenarious and parameter variations

Interaction with designers (SW, electronics, mechanists, and /or chemists) to ensure optimal product design.

ELECTRONIC DESIGN

Some of the services the company offers are:

- Environmentally challenged products development, containing analogue and digital circuits

- Development of control-, servo- and measuring systems

- Construction of electronic solutions and circuit cards using the latest development tools

- Devotek use CADSTAR scematic tool and PCB software

EMBEDDED DEVELOPMENT

Hardware development

32/16/8 bit microcontroller and processor design

Soft core processors

System on chip

FPGA

DSP

Embedded system sensor interface design (analog / digital)

- Temperature

- Pressure

- Acceleration (G-force)

- IMU (intertial measurement unit)

- Torque

- Stretch

- Position

- Humidity

- Light intensity

- Custom sensor interfaces

Actuator interfaces

- Electrical

- Hydraulic

- Servo

Embedded Linux

Windows CE

Windows XP embedded

RTOS

CAN bus nodes and masters

Embedded TCP/IP & UDP/IP

Hart bus

Current loop interfaces (4-20 ma) to embedded systems

Schematic design

PCB design

Ruggedization

Extended temperature

Software development

C / C++ code development

Model driven Development (UML/SDL)

Project lead / mentoring

Debugging

Testing

Software testing

Test suites

Test lab

Logging

Log analysis

Improvement of customer test processes

Training

Model driven testing

MQtool

Prototype to measure user experienced quality

Independent benchmarking and quality measurement

Analog and digital modem testing

Telecom network architecture and e2e solutions

Embedded GSM, GPRS, UMTS modem design-in & implementation

GPS for embedded systems

Plan, evaluate and optimize network architecture

Develop, test and troubleshoot end-to-end solutions in mobile networks

Competence and services within GSM and UMTS data communication

Embedded web servers and applications

Embedded data streaming and embedded data logging solutions

SYSTEMS ENGINEERING

An effective way of doing product development and engineering to make sure that:

- The customer gets the solution he expects

- At the expected time

- At the expected cost

Devotek provides systems architects to manage the systems engineering process:

- Understand and validate the problem and the need of the customer

- Establish the most feasible concept for the solution consistent with the needs

- Develop and implement the architecture of that concept

- Develop the assembly structure of that architecture

- Test and integrate the assembly structure

- Document everything sufficient to support the development phase, the maintenance phase, midlife updates, etc.

Devotek do complete customer projects by tailoring the SE process to the reality of each project.

Devotek counsel customer projects accordingly

Devotek offers courses in Systems Engineering

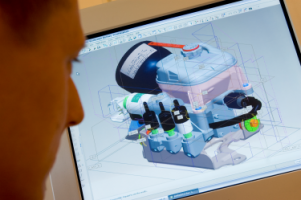

MECHANICAL DEVELOPMENT & DESIGN

The company's mechanical designers have a broad experience within different branches and products. The company focuses on that already in phase of construction the later phases as production, test and validation shall be taken into consideration

Some of the services the company offers are:

-

Mechanical construction and design, 3D by using tools as ProEngineer, Ideas, NX, SolidWorks

-

Development of dynamic systems

-

Design of hydraulic solutions

-

Electro motor actuation

-

Gear design & optimalization (KISSoft)

-

Kinematics’ validation & optimalization

-

Industrializing, preparation for serial production

-

Take out of production drawings

-

Configuration management and document control (Teamcenter)

TEST & MEASUREMENT

Product validation, testing and measurement

Devotek has a well equipped test lab with test engineers beeing able to cover a wide specter of diciplines. In addition to internal resourses, we work in cooperation with external test houses. Devotek has a wide knowledge of National Instruments software and hardware. Its temperature chambers can be rented for short and longtime tests.

Typical test categories:

-

Temperature,humidity and salt mist tests

-

Durability tests

-

Vibration tests

-

Support on existing test systems

-

Instrumentation of installation

-

Development of test rigs

-

Field testing and instrumentation

-

Prototype and small series testing

A description of most used test equipment:

Temperature and humidity testing

- 6 temperature chambers (-40 +180°C) from ACS, Weiss and Vøtsch

- 1 humidity & temperature chamber (-40 + 180°C)

- PC controlled by Winkratos + Simpati software

Data aquisition and logger systems

- National Instruments DAQ systems and software

- Agilent

- Micromusycs (IMC) portable logger

- Famos curve manger and analysis tool

Sensors and transducers

- Load cells

- Moment transducers

- Flow meters

- Position sensors

- Temperature sensors

MANUFACTURING

Kongsberg Devotek`s workshop and lab consists of machines for production of parts with high precision. The company does milling and turning. Additionally it can assist with construction, drawings, measurements.

From 3D model to complete finished part

By using EdgeCam the company can import 3D CAD models directly from constructor into its machines. Then the operator can simulate the production process and plan the use of tools. The data will then be transferred directly into the computer on the machines.

Other production

- Assembly of internal manufactured parts

••Assembly of parts from customers

••Rapid prototyping

••Soft moulding - Measuring

- Surface measurements

- Mitutoyo Euro CNC controlled measurement robot

- Mitutoyo Video microscope

- Handheld micrometers

- Precisionsveights

MACHINES FOR PRODUCTION

Examples of the machines and production equipment:

CNC Controlled Machines

- Mori Seiki NMV 5000 DCG - 5 axis

- Cincinnati Arrow 1000 – 4 axis

- EdgeCam- with export to Pro E og Solid Works

CNC Controlled Turning Machines

- Puma 4 akse + sub spindle

- EdgeCam - with export to Pro E og Solid Works.

Measurement Lab

- Equipment for surface measurements

- Mitutoyo Euro CNC measurement machine

- Mitutoyo Video microskope

- Handheld micrometer

- Precision weights

- Temperature controlled lab

Other machines

- Manual milling machines

- Manual turning machines

- Welding equipment

- Advanced saws

CUSTOMERS / REFERENCES

- Hernis PT-12

- Badger Explorer

- BAE Systems

- Rotator

- Coventure

- SAAB Skeldar

- Iveco

- Devotek og Rotator er samarbeidspartnere

- Aker Solutions/Aker MH

- CRV7 - 70 mm Laser Guided Missile

- Remote Weapon Station

- RWS Protector

- Lav Energi Aktuator, LEA

- LuK ESG Hybrid DCT girsystem

- Toyota SMT AMT

- Automatisering av drivlinjer

- Tanken som skal redde liv pa havbunnen

Automation of transmission lines

Typical applications:

- Clutch features

- Gearshift features

- AMT's

- DCT's

- Hybridization by using hydraulics as well as electric actuator principles.

The company can offer assistance in all stages of the development process, from idea, through the prototype phase, the series clearly and fully qualified product. Devotek is a system developer, and automation of drivelines is the core of its expertise. Over the years, its customer range has been expanded to include almost all European and many Asian automakers: Toyota SMT AMT

How Devotek helped: Turn-Key development and Tier 1 supplier responsibility.

The result:

Proven market performance since 1998!

New evolutions being incorporated into future models

Low Energy Actuator, LEA

The Company's technical challenge:

To replace existing technology with a "hold-and-release" actuator for safety applications, with the following characteristics:

• be able to tighten up and be released again and again

• extremely low energy consuming

• extremely fast

What Devotek did:

• generated, evaluated and concluded that the concept

• Responsible for the design and production

• Responsible for qualification

• Testing of the product

Remote Weapon Station

Kongsberg Devotek has delivered "main Azimut gear" to the RWS.

Deliverables included:

- Developing a backlash-free azimuth system with manual override

- Complete mechanical design

- Specifying the servo motor drivers, sensors and gears

- Component Selection

- Production and verification of prototypes

BAE-Haegglunds – Complete drive train development

SEP is a family of vehicles that provide superior survivability and a unique degree of flexibility to meet the needs of current and future forces around the globe. SEP was shown during the IDEX exhibition in Abu Dhabi (22 to 26 February 2009).

"The choice of Kongsberg Devotek as a result of a long search for good partners for the SEP program to benefit our customers," says Hans Häggberg, purchasing director at BAE Systems Hägglunds. "We have a long and positive experience in. cooperation with Norwegian industry, so this partnership lays a strong foundation for continued success, so that we can exploit our people, products and technology worldwide to meet our customers' needs. "

Military forces around the world will benefit from the SEP. The vehicle is far ahead of their competitors in innovation with a focus on low costs in its lifetime.

Badger Explorer

Kongsberg Devotek has assisted Badger in the development of a concept for exploration of the seabed. Through this work it has faced great challenges and Devotek is proud to be part of this epoch-making team.

Devotek AS

- PO Box 384, NO 3604, Kongsberg, Norway

- +47 90 77 04 00

- Kjersti.Engen@semcon.com

- www.devotek.com